When it comes to choosing the right grease for your machinery, the decision between Number 1 and Number 2 grease can be crucial. Understanding the differences between these two types of grease can help you make an informed decision for optimal equipment performance and longevity.

Credit: natoli.com

What is NLGI Consistency Number?

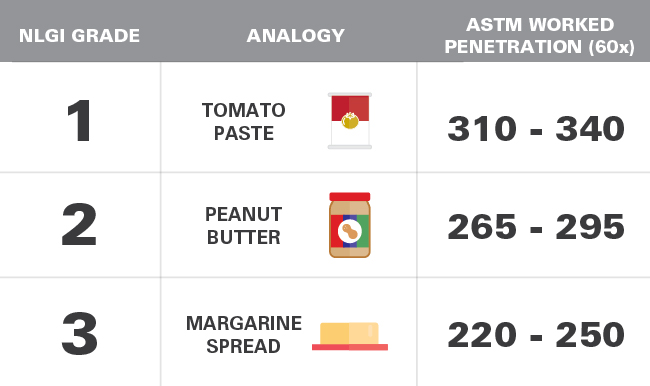

The NLGI consistency number, also known as NLGI grade, expresses the relative hardness of a grease used for lubrication. It is specified by the standard classification of lubricating grease established by the National Lubricating Grease Institute (NLGI). The NLGI consistency number is an essential factor to consider when selecting the appropriate grease for your equipment.

Understanding NLGI Grades

The NLGI consistency number ranges from 000 to 6, with 000 being the softest and 6 being the hardest. Number 1 grease falls within the NLGI consistency number range of 1 to 2, while Number 2 grease falls within the range of 2 to 3. This grading system helps users determine the thickness and stiffness of the grease, which is crucial for various applications and operating conditions.

Important Factors to Consider

When choosing between Number 1 and Number 2 grease, several important factors need to be taken into account:

- Operating Temperature: Consider the temperature range in which your equipment operates. Number 2 grease may be more suitable for higher operating temperatures, while Number 1 grease can be ideal for lower temperature conditions.

- Load-Bearing Capacity: Evaluate the load-bearing capacity of your machinery. Number 2 grease typically offers higher load-carrying capabilities compared to Number 1 grease.

- Application Requirements: Assess the specific application requirements of your equipment to determine the most suitable NLGI grade for optimal performance and protection.

Benefits of Number 1 Grease

Number 1 grease, with its lower NLGI consistency number, offers several benefits for certain applications:

- Enhanced pumpability and flow in colder temperatures

- Improved performance in low-speed and high-load conditions

- Greater ability to penetrate tight spaces for effective lubrication

Advantages of Number 2 Grease

Number 2 grease, falling within a slightly higher NLGI consistency range, provides distinct advantages for specific usage scenarios:

- Superior resistance to softening and leakage at elevated temperatures

- Enhanced protection under heavy loads and high-speed operations

- Longer-lasting lubrication in demanding industrial applications

Credit: www.nyelubricants.com

Choosing the Right Grease for Your Equipment

Ultimately, the decision between Number 1 and Number 2 grease depends on a careful assessment of your equipment’s operating conditions, load requirements, and environmental factors. It is essential to consider the manufacturer’s recommendations, equipment specifications, and NLGI grade guidelines to make an informed choice.

Seeking Expert Guidance

If you are unsure about the appropriate grease for your specific machinery, consulting with lubrication experts or equipment manufacturers can provide valuable insights and recommendations. They can offer tailored advice based on your equipment type, operating conditions, and performance expectations.

Frequently Asked Questions

Should I Use #1 Or #2 Grease?

Use #1 grease for low-speed, high-load applications and #2 grease for general-purpose lubrication needs.

What Is The Difference Between Nlgi #1 And Ngl2?

NLGI #1 is softer than NLGI #2 grease, with lower viscosity and better flow.

What Is Nlgi-1 Grease Used For?

NLGI-1 grease is used for low-speed and high-load applications, such as in industrial equipment and heavy machinery. It provides solid protection and lubrication in extreme conditions.

What Is The Difference Between Ep-1 And Ep2 Grease?

EP-1 and EP-2 grease differ in their NLGI consistency number, which indicates their relative hardness. EP-1 has a lower consistency, making it less viscous, while EP-2 has a higher consistency, making it thicker. The choice between the two depends on the specific lubrication requirements of the application.

Conclusion

Choosing the right grease, whether Number 1 or Number 2, is crucial for maintaining the efficiency, reliability, and longevity of your machinery. By understanding the differences between these NLGI grades and considering the specific requirements of your equipment, you can make an informed decision to optimize performance and minimize wear and tear.