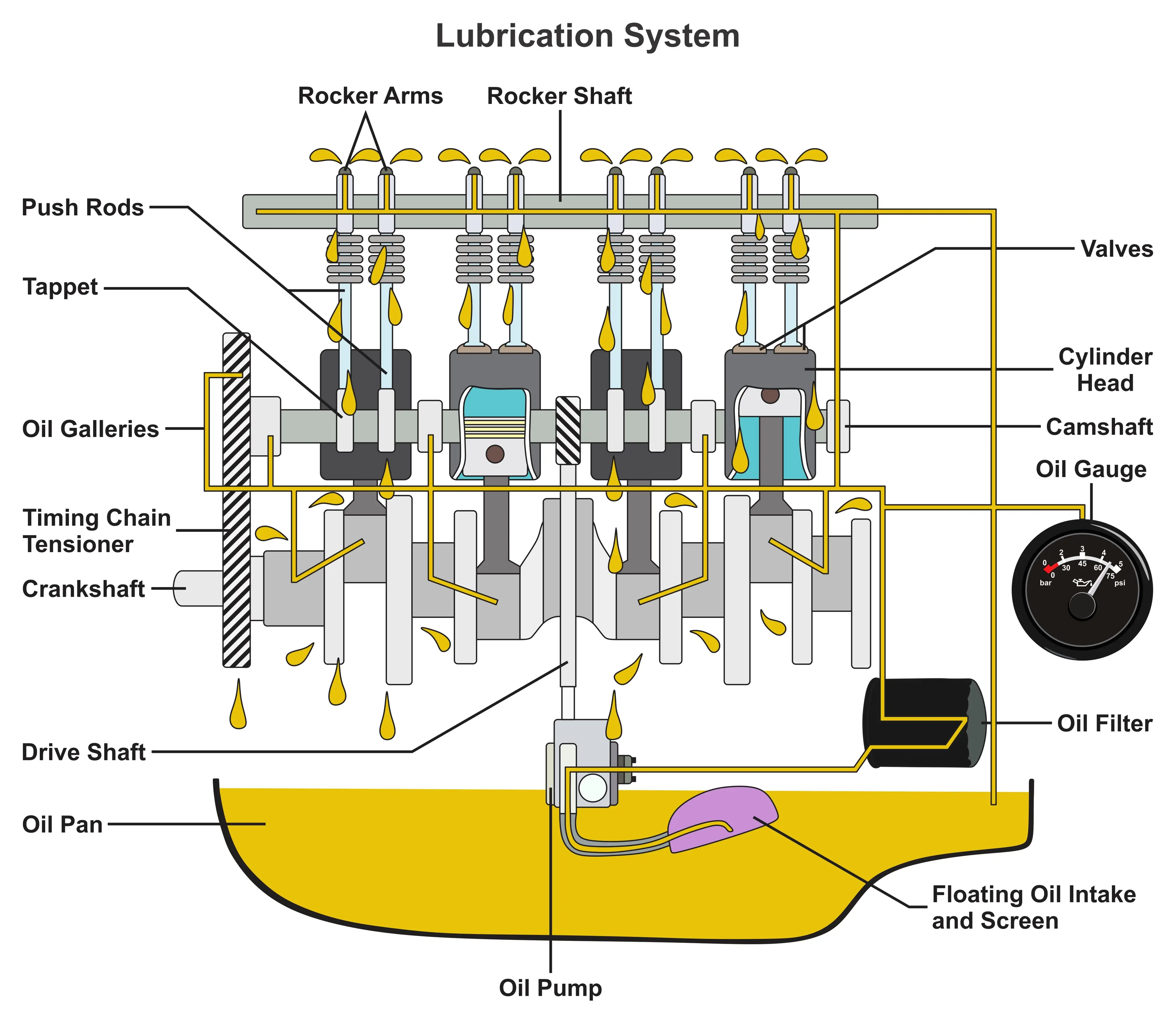

An engine lubrication system works by circulating oil throughout the engine to reduce friction between moving parts, prevent overheating, and protect against wear and tear. The oil is stored in the oil sump or pan when the engine is not running and is pumped through a filter to remove impurities before being distributed to various parts of the engine via oil galleries.

The oil is then collected and returned to the sump for reuse. This system is essential for keeping the engine running smoothly and efficiently. Proper lubrication of an engine is crucial for its longevity and performance. The engine lubrication system helps to maintain optimal engine temperature and prevent damage to the engine components.

We will discuss the various components of an engine lubrication system and how they work together to keep the engine running smoothly. We will also explore the different types of lubricants used in engines and the importance of regular oil changes. Understanding how an engine lubrication system works is essential for any vehicle owner or mechanic.

The Heart Of Lubrication: The Oil Pump

The engine lubrication system is a crucial component of a vehicle’s operation. The oil pump serves as the heart of the lubrication process, facilitating the movement of oil throughout the engine. This process is powered by a belt and pulley system that harnesses the engine’s power to drive the pump. The journey of the oil begins in the sump, where it is then drawn into the pump through a suction mechanism. Once inside the pump, the oil is pressurized to ensure proper lubrication of the engine components. After passing through the oil filter to remove any contaminants, the oil flows through the engine to lubricate vital parts such as the crankshaft, bearings, pistons, and camshaft. This continuous circulation of oil is essential for reducing friction and heat, thus optimizing the engine’s performance and longevity.

Credit: www.gulfoilltd.com

The Filtration Process: Ensuring Purity

The engine lubrication system works by filtering and removing contaminants from the oil to ensure its purity and effectiveness. The oil strainer plays a crucial role as the first line of defense, collecting and filtering oil from the sump through suction created by the oil pump. Following this, the oil filter works to remove any dust particles present in the oil, supplying clean oil to the oil lines. The oil then flows through the engine’s components, lubricating the crankshaft bearings, piston, camshaft, and other vital parts. This process allows the oil to absorb heat and return to the sump for heat dissipation, ensuring the engine stays properly lubricated and functioning efficiently.

Regulating Oil Pressure: A Critical Balance

When it comes to the engine lubrication system, regulating oil pressure is of critical importance. The oil pressure regulator plays a crucial role in maintaining stability. It ensures that the oil pressure level is properly maintained, which has a direct impact on engine performance. Proper oil pressure is essential for the smooth operation of engine components and to prevent excessive wear and tear.

The oil pressure regulator works in conjunction with other components such as the oil pump, oil filter, and bypass valve. These components work together to ensure that clean and properly pressurized oil is supplied to the engine. The oil pump sucks oil from the sump through a strainer, and the oil filter removes any dust particles before supplying clean oil to the oil lines.

The oil from the main gallery flows through holes drilled inside the crankshaft and main bearings to lubricate them. Additionally, an oil sprout connected to the gallery forces the oil upwards to lubricate the piston and its parts from the inside. Another gallery and associated sprouts help in lubricating the camshaft, valves, and valve springs. After lubricating the engine parts, the oil flows downwards through a separate passage and eventually gets collected in the sump.

Overall, the engine lubrication system ensures that all moving parts are adequately lubricated, reducing friction and heat buildup, and extending the life of the engine.

Credit: www.grc.nasa.gov

The Lubrication Circuit: Pathways To Protection

|

How Does an Engine Lubrication System Work? Main Oil Gallery: Distributing Vital LubricationThe engine lubrication system plays a crucial role in protecting the engine’s moving parts and ensuring its smooth operation. At the heart of this system is the main oil gallery, which distributes vital lubrication throughout the engine. The main oil gallery is responsible for supplying oil to various components, such as the crankshaft and bearings. The crankshaft and bearings are a central focus of the lubrication system. The oil flows through the holes drilled inside the crankshaft and main bearings, providing essential lubrication to prevent metal-on-metal contact and reduce friction. This lubrication ensures smooth rotation of the crankshaft and prolongs its lifespan. |

Reaching The Upper Engine: Pistons And Valves

The engine lubrication system is responsible for keeping the engine’s moving parts running smoothly and preventing wear and tear. One of the most critical components of the system is the pistons and valves. Proper lubrication of these components can extend their lifespan and improve engine performance. When it comes to lubricating the pistons, it’s essential to ensure that both the inside and outside of the component are coated with oil. This lubrication helps reduce friction and heat buildup, which can damage the engine. Additionally, keeping the camshaft smooth is crucial for the valve train’s proper functioning. Lubrication of the camshaft and valve springs ensures that they move freely and do not wear out prematurely.

Heat Management: The Oil’s Thermal Role

An engine lubrication system works by ensuring that all moving parts are lubricated with oil to reduce friction and prevent damage from heat buildup. One important aspect of the system is heat management, which is where oil plays a crucial role in maintaining proper temperature levels. The oil sump is not just for storage, it also helps dissipate heat by releasing it to the surrounding air. Additionally, the oil cooler is an essential heat exchanger that helps maintain optimal temperature levels by cooling the oil that has absorbed heat from the engine. Overall, the lubrication system is vital for keeping the engine running smoothly and preventing damage from heat and friction.

Advanced Lubrication Components: Enhancing Performance

When it comes to understanding how an engine lubrication system works, it’s important to explore the advanced lubrication components that enhance performance. One such component is the pressure relief valve, which plays a crucial role in preventing excess pressure within the system. This valve ensures that the oil flow is regulated and controlled, preventing any potential damage to the engine. Another essential component is the oil control rings, which serve as the seal of efficiency. These rings help to control the amount of oil that enters the combustion chamber, ensuring optimal lubrication while minimizing oil consumption.

The lubrication system works in a cycle, starting with the oil pump receiving power from the engine. The oil strainer collects and filters the oil from the sump, while the oil pressure regulator maintains the proper oil pressure level. The oil filter removes any dust particles, and the oil flows through the main gallery, lubricating the crankshaft and main bearings. It then moves upward to lubricate the piston and its parts, and also reaches the camshaft, valves, and valve springs through separate galleries and sprouts. Finally, the oil collects back in the sump, completing the cycle.

The Return Journey: Completing The Cycle

The engine lubrication system works by using an oil pump to suck oil from the sump, filter it, and maintain proper pressure levels before distributing it through galleries to lubricate various engine parts. Once the oil has run through the engine and absorbed heat, it returns to the sump to release the heat into the surrounding air.

The engine lubrication system plays a crucial role in keeping the engine running smoothly and efficiently. One important aspect of this system is the return journey of the oil, completing the cycle. Gravity plays a significant role in this process, as the oil descends back to the sump after it has run through the engine and absorbed heat. The oil sump, also known as the oil pan, acts as a reservoir where the lubricant is stored when the engine is not running. It not only holds the oil but also helps dissipate heat. Regular oil changes are essential to maintain the proper functioning of the lubrication system and ensure optimal engine performance. By removing old oil and replacing it with fresh oil, you can prevent the buildup of contaminants and extend the life of your engine.

Credit: www.wolflubes.com

Frequently Asked Questions

How Does An Engine Stay Lubricated?

The engine stays lubricated through an oil pump that circulates oil to the main bearings, crankshaft, and other engine components. The oil is filtered to remove impurities and then returned to the sump for recirculation.

How Does Oil Travel Through An Engine?

Oil travels through an engine by being pumped up to the crankshaft bearings, then moving through oil holes in the crankshaft to the rod bearings. From there, it flows through an oil line to the cylinder head. Finally, the oil returns to the oil pan or sump where it can be reused.

The lubrication system ensures that the engine’s moving parts are properly lubricated to reduce friction and wear.

How Does Oil Return To The Oil Pan?

Oil returns to the oil pan by flowing through various paths from the engine, eventually reaching the bottom sump under pressure. This process allows the oil to release heat and dissipate, aiding in the lubrication system’s efficiency.

How Does Lubrication Work?

A lubrication system uses a material between two rubbing surfaces to reduce friction and wear. In an engine, oil is pumped from the sump by the oil pump and filtered before being sent to the main bearings of the crankshaft.

The oil then flows through the crankshaft, rod bearings, and oil line to the cylinder head, lubricating the engine’s moving parts. After absorbing heat, the oil returns to the sump where it can dissipate heat.

Conclusion

The engine lubrication system is crucial for reducing friction and wear between moving parts. The oil pump, filter, and galleries work together to ensure proper lubrication throughout the engine. Understanding how this system functions is vital for maintaining the longevity and efficiency of an engine.