EAL (Environmentally Acceptable Lubricants) and EPA (Environmental Protection Agency) provide lists of eco-friendly lubricants. These lubricants minimize environmental impact and comply with strict regulatory standards.

Environmentally Acceptable Lubricants (EALs) are essential for industries aiming to reduce their ecological footprint. The Environmental Protection Agency (EPA) supports this initiative by offering a list of approved lubricants that meet stringent environmental criteria. These lubricants are biodegradable, minimally toxic, and non-bioaccumulative.

Using EALs helps industries comply with regulations while protecting natural resources. This practice is crucial for sectors like marine, agriculture, and construction, where lubricant spillage can harm ecosystems. Opting for EALs ensures operational efficiency without compromising environmental integrity.

Credit: www.amazon.com

Introduction To Eal & Epa

The environment needs protection, and lubricants play a role. Environmentally Acceptable Lubricants (EALs) are special lubricants. They cause less harm to nature. The Environmental Protection Agency (EPA) ensures these lubricants are safe.

The Rise Of Environmentally Acceptable Lubricants

Lubricants are crucial in machinery. Traditional lubricants harm the environment. EALs emerged as a solution. They are made from biodegradable materials. This means they break down easily. They do not pollute water or soil.

Industries started using EALs more. They wanted to reduce their environmental impact. This shift helped protect ecosystems. EALs are now common in many sectors. They are used in marine, agriculture, and industrial applications.

Epa Guidelines For Eals

The EPA has strict guidelines for EALs. These rules ensure the lubricants are safe for the environment. EPA tests these lubricants before approving them. They look at several factors:

- Biodegradability: Lubricants must break down quickly.

- Toxicity: They should not harm aquatic life.

- Bioaccumulation: Lubricants should not build up in organisms.

If a lubricant meets these criteria, the EPA approves it. This helps protect nature from harmful chemicals.

| Criteria | Description |

|---|---|

| Biodegradability | Lubricants must break down quickly. |

| Toxicity | Should not harm aquatic life. |

| Bioaccumulation | Should not build up in organisms. |

These guidelines ensure that EALs are safe to use. They help industries make better choices. The EPA helps protect our world.

Credit: www.bioblend.com

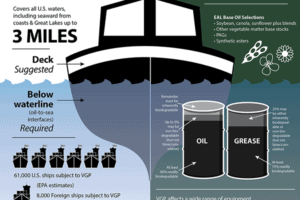

Criteria For Eal Selection

Choosing the right Environmentally Acceptable Lubricants (EALs) is vital for sustainable operations. These lubricants must meet specific criteria to ensure they are safe for the environment and effective in their application. Below, we explore the key criteria for selecting EALs.

Biodegradability And Toxicity

Biodegradability is an essential factor in EAL selection. A good EAL should break down quickly in the environment. This minimizes its impact on ecosystems.

Toxicity measures how harmful the lubricant is to aquatic and terrestrial life. Lower toxicity levels are better. This ensures minimal harm to plants and animals.

| Criteria | Description |

|---|---|

| Biodegradability | Ability to break down naturally and safely. |

| Toxicity | Measure of how harmful the substance is to living organisms. |

Performance Standards

Performance standards ensure that EALs perform effectively in their intended applications. They must provide lubrication and protection for machinery. This is crucial for operational efficiency.

Several industry standards guide EAL performance. These include ASTM, ISO, and SAE standards. Compliance with these standards indicates a reliable product.

- ASTM Standards: Set by the American Society for Testing and Materials.

- ISO Standards: International standards for quality and safety.

- SAE Standards: Established by the Society of Automotive Engineers.

Top Picks For Marine Applications

Choosing the right Environmentally Acceptable Lubricants (EALs) is crucial for marine applications. EALs protect marine environments and ensure optimal performance. Let’s explore the top picks for hydraulic fluids and gear oils.

Hydraulic Fluids

Hydraulic systems need reliable and eco-friendly lubricants. Here are some top hydraulic fluids:

- BioHydraulic HF Series: This series offers excellent oxidation stability. It protects against wear and rust.

- EnviroLogic 3046: This fluid is biodegradable and non-toxic. It provides superior lubrication and protection.

- Panolin HLP SYNTH: Known for its high performance, it ensures long service life and reduces maintenance costs.

Gear Oils

Gear oils need to be durable and environmentally safe. Here are some top gear oils:

- EcoGear 320: This oil provides excellent thermal stability and corrosion protection.

- BioGear S 150: This gear oil is biodegradable and has high load-carrying capacity.

- REWITEC G5: Known for reducing friction and wear, it extends the lifespan of gear systems.

Credit: lelubricants.com

Leading Choices For Industrial Use

The EAL & EPA Environmentally Acceptable Lubricants List offers several top choices. These lubricants are perfect for various industrial applications. They ensure environmental safety and efficient performance.

Greases

Greases are essential in many industrial settings. They reduce friction and protect machinery. Below are some top EAL & EPA-approved greases:

- BioGrease EP 2: This grease is great for heavy-duty applications. It provides excellent wear protection.

- EcoGrease 800: Known for its long-lasting properties. It is perfect for high-temperature environments.

- MarineGrease Bio: Ideal for marine applications. It offers superior water resistance.

Compressor Oils

Compressor oils are vital for the smooth operation of compressors. They ensure long-lasting performance and protect against wear. Here are some leading choices:

- EcoCompressor Oil 46: Provides excellent thermal stability. It is suitable for a wide range of compressors.

- BioCompressor Oil 68: This oil is biodegradable. It offers exceptional lubrication under extreme conditions.

- GreenCompressor Oil 100: Known for its high oxidation stability. It ensures longer oil life and reduced maintenance.

| Lubricant Type | Key Feature | Best For |

|---|---|---|

| BioGrease EP 2 | Heavy-duty applications | Excellent wear protection |

| EcoGrease 800 | Long-lasting properties | High-temperature environments |

| MarineGrease Bio | Superior water resistance | Marine applications |

| EcoCompressor Oil 46 | Thermal stability | Wide range of compressors |

| BioCompressor Oil 68 | Biodegradable | Extreme conditions |

| GreenCompressor Oil 100 | Oxidation stability | Longer oil life |

Innovations In Eal Formulations

Environmental concerns have driven the development of Environmentally Acceptable Lubricants (EALs). These lubricants reduce the impact on ecosystems. Recent innovations focus on making EALs more effective and durable. Two key types of EALs have shown significant advancements: Synthetic Esters and Polyalkylene Glycols.

Synthetic Esters

Synthetic Esters are a revolutionary type of lubricant. They are made from renewable resources like vegetable oils. These esters are biodegradable and have low toxicity. This makes them safe for the environment.

Synthetic Esters offer excellent performance in extreme conditions. They have high thermal stability and low volatility. This means they do not evaporate easily. They also offer good lubricity, which reduces wear and tear on machinery.

Here is a table showing the benefits of Synthetic Esters:

| Benefit | Description |

|---|---|

| Biodegradable | Breaks down naturally in the environment. |

| Low Toxicity | Safe for plants and animals. |

| Thermal Stability | Performs well under high temperatures. |

| Low Volatility | Does not evaporate easily. |

| Good Lubricity | Reduces friction and wear. |

Polyalkylene Glycols

Polyalkylene Glycols (PAGs) are another type of advanced EAL. They are synthetic fluids known for their excellent performance. PAGs are highly soluble in water. This makes them easy to clean up in case of spills.

PAGs have a unique property. They do not form sludge or deposits. This keeps machinery clean and running smoothly. These lubricants also have a high viscosity index. This means they maintain their thickness over a wide range of temperatures.

Key features of Polyalkylene Glycols include:

- Water Solubility

- No Sludge Formation

- High Viscosity Index

- Good Oxidation Stability

Both Synthetic Esters and Polyalkylene Glycols are paving the way for the future of EALs. They ensure machines run smoothly while keeping the planet safe.

Case Studies: Success Stories

Case Studies: Success Stories showcase the real-world impact of the EAL & EPA Environmentally Acceptable Lubricants List. These success stories illustrate how different sectors have successfully implemented environmentally friendly lubricants. The case studies highlight the benefits achieved by these sectors.

Maritime Sector Implementations

The maritime sector has greatly benefited from using EAL & EPA Environmentally Acceptable Lubricants. Ships using these lubricants have reported fewer leaks and spills. This reduces environmental damage and maintenance costs.

A notable example is a shipping company that switched to these lubricants. They observed a 25% reduction in operational costs within the first year. This switch also led to compliance with international environmental regulations.

Key benefits:

- Reduced maintenance costs

- Lower environmental impact

- Compliance with international regulations

Industrial Transformations

Industries have also embraced EAL & EPA Environmentally Acceptable Lubricants. A manufacturing plant reported a significant improvement in machine efficiency. The plant saw a 30% increase in productivity after using these lubricants.

Another case involved an automotive factory. The factory experienced a 20% reduction in downtime due to better lubricant performance. This led to higher production rates and satisfied customers.

Key benefits:

- Improved machine efficiency

- Increased productivity

- Reduced downtime

| Sector | Benefit | Percentage Improvement |

|---|---|---|

| Maritime | Operational cost reduction | 25% |

| Industrial | Productivity increase | 30% |

| Automotive | Downtime reduction | 20% |

Challenges And Solutions

Understanding the challenges and solutions involved with the EAL & EPA Environmentally Acceptable Lubricants List is crucial. This guide highlights the key issues and effective strategies for overcoming them.

Compatibility Issues

One common challenge is compatibility issues. Not all equipment can use environmentally acceptable lubricants (EALs). For example, older machinery may face wear and tear when switching to EALs. This can lead to unexpected downtime and maintenance costs.

To address this, conduct a compatibility assessment. Check if the lubricant suits your machinery. Manufacturers often provide compatibility charts. Consult these resources to avoid potential issues.

Another solution is to phase in the new lubricant gradually. Start with a small batch and observe the performance. This minimizes risks and helps identify any problems early.

Cost-benefit Analysis

The cost-benefit analysis is critical. Environmentally acceptable lubricants often come with a higher upfront cost. This can be a barrier for many businesses.

Consider the long-term benefits. EALs often have a longer lifespan, reducing the need for frequent replacements. This can lower overall maintenance costs. Additionally, using EALs can enhance your company’s reputation for sustainability. This can attract eco-conscious customers and partners.

Here’s a quick comparison table for better understanding:

| Aspect | Traditional Lubricants | Environmentally Acceptable Lubricants (EALs) |

|---|---|---|

| Initial Cost | Lower | Higher |

| Maintenance Frequency | Higher | Lower |

| Sustainability | Low | High |

| Reputation | Neutral | Positive |

Conduct a detailed cost-benefit analysis before making a decision. Consider all factors to determine the best choice for your business.

Future Directions

The field of Environmentally Acceptable Lubricants (EALs) is evolving rapidly. As awareness of environmental concerns grows, the demand for EALs increases. This section explores future directions, focusing on regulatory developments and technological advancements.

Regulatory Developments

Government regulations play a crucial role in shaping the EAL market. New policies aim to reduce harmful environmental impacts. These policies drive the adoption of EALs in various industries.

Stricter guidelines are being introduced globally. These guidelines require the use of biodegradable and non-toxic lubricants. Compliance with these regulations is mandatory for many industries.

Below is a table summarizing some key regulatory bodies and their guidelines:

| Regulatory Body | Guidelines |

|---|---|

| EPA (USA) | Vessel General Permit (VGP) |

| EU Ecolabel | Criteria for Lubricants |

| IMO | MARPOL Annex V |

Technological Advancements

Innovations in lubricant technology are paving the way for better EALs. Researchers are developing new formulations that improve performance and environmental impact.

Some key technological advancements include:

- Bio-based materials: These materials offer better biodegradability and lower toxicity.

- Nanotechnology: Enhances lubricant properties such as friction reduction and wear resistance.

- Synthetic esters: Provide superior performance in extreme conditions.

R&D investments are crucial for the future of EALs. Companies that invest in research will lead the market. Below is an example of how these advancements benefit various sectors:

| Sector | Benefit |

|---|---|

| Marine | Reduced water pollution |

| Agriculture | Improved soil health |

| Automotive | Enhanced engine efficiency |

Frequently Asked Questions

What Are Eal Approved Lubricants?

EAL approved lubricants are environmentally acceptable lubricants. They meet strict environmental standards for biodegradability, toxicity, and bioaccumulation.

What Is An Environmentally Acceptable Lubricant?

An environmentally acceptable lubricant (EAL) is biodegradable, non-toxic, and minimizes environmental impact. EALs are designed to reduce pollution.

Which Engine Oil Is Most Environmentally Friendly?

The most environmentally friendly engine oil is synthetic or bio-based oil. These oils reduce emissions and improve fuel efficiency. Choose brands with eco-friendly certifications for the best impact.

What Is A Biodegradable Lubricant?

A biodegradable lubricant breaks down naturally, minimizing environmental impact. It’s eco-friendly, safe, and reduces pollution.

Conclusion

Choosing the right lubricants is crucial for environmental sustainability. EAL and EPA-approved options offer effective and eco-friendly solutions. Prioritize these choices to ensure compliance and protect the planet. Make informed decisions for a greener future with environmentally acceptable lubricants. Your commitment to eco-friendly practices can make a significant difference.