Aircraft line maintenance engine oil is essential for lubrication and cooling of aircraft engines. Regular oil changes ensure optimal engine performance and longevity.

The type of oil used, such as ashless dispersant or mineral oil, plays a crucial role in maintaining engine health. Aircraft engines rely on specialized oils to withstand high temperatures and provide proper lubrication. Unlike automotive oil, aviation oil contains additives suitable for air-cooled piston engines.

Proper maintenance, including routine oil analysis, is key to ensuring the reliability and efficiency of aircraft engines. By following recommended lubrication practices, aircraft operators can maximize engine performance and safety.

Introduction To Aircraft Line Maintenance

Aircraft line maintenance is an essential aspect of ensuring the safety and airworthiness of an aircraft. It encompasses regular inspections, checks, and minor repairs that are conducted on the aircraft to maintain its operational efficiency and safety standards. One critical component of aircraft line maintenance is the engine oil, which plays a vital role in the proper functioning of the aircraft’s engine.

Importance Of Engine Oil

Engine oil is crucial for the smooth operation and longevity of an aircraft’s engine. It provides lubrication to the engine components, reducing friction and minimizing wear and tear. Additionally, engine oil aids in dissipating heat, preventing corrosion, and sealing piston rings, contributing to the overall efficiency and performance of the engine.

Efficiency In Line Maintenance

Efficient line maintenance is paramount for ensuring the continuous airworthiness of an aircraft. Regular checks and timely maintenance activities, including engine oil inspections and changes, are essential to prevent potential issues and maintain the reliability and safety of the aircraft. By adhering to a stringent maintenance schedule, operators can minimize downtime and enhance the overall operational efficiency of the aircraft.

Credit: www.aopa.org

Selecting The Right Engine Oil

Selecting the right engine oil for aircraft line maintenance is crucial. Aircraft engines typically use mineral oils with ashless dispersant additives to scavenge debris effectively. Regular oil analysis and following manufacturer recommendations ensure optimal engine performance and longevity.

Selecting the Right Engine Oil When it comes to aircraft line maintenance, engine oil is an essential component that helps ensure the proper functioning of the aircraft. Choosing the right engine oil can be a daunting task, especially for those who are new to the field. It’s important to consider factors such as the type of oil, its benefits, and how often it needs to be changed. In this blog post, we’ll focus on selecting the right engine oil and cover the following subheadings: Mineral vs. Synthetic Oils and Ashless Dispersant Oils and Their Benefits.Mineral Vs. Synthetic Oils

Mineral oils are petroleum-based oils that are refined to meet the required specifications. They are commonly used in aircraft engines due to their availability and low cost. On the other hand, synthetic oils are man-made and have a higher molecular weight than mineral oils. They offer better resistance to thermal breakdown and are more stable in extreme temperatures. While synthetic oils are more expensive than mineral oils, they offer better performance and longer-lasting protection.Ashless Dispersant Oils And Their Benefits

Ashless dispersant oils (AD oils) are a type of mineral oil that contains additives to help remove debris from the engine and carry it to the filter or screen. They are used in most modern aircraft engines due to their ability to prevent engine deposits and prolong engine life. AD oils also offer better corrosion protection and maintain their viscosity over a longer period. In addition, they require fewer oil changes compared to non-AD oils, which can save time and money. When selecting the right engine oil for aircraft line maintenance, it’s important to consider factors such as the type of oil, its benefits, and how often it needs to be changed. Mineral oils are commonly used due to their availability and low cost, while synthetic oils offer better performance and longer-lasting protection. Ashless dispersant oils are recommended for most modern aircraft engines due to their ability to prevent engine deposits, prolong engine life, and require fewer oil changes. By selecting the right engine oil, you can help ensure the proper functioning and longevity of the aircraft engine.Optimizing Oil Change Intervals

When it comes to aircraft line maintenance, optimizing oil change intervals is crucial for the efficient operation of the engines. Determining the ideal frequency and monitoring engine health are essential aspects of this process. By understanding these factors, aviation professionals can ensure that the engines are well-maintained and perform at their best.

Determining Ideal Frequency

The ideal frequency for changing engine oil in aircraft is determined by various factors, including the type of aircraft, engine model, operating conditions, and oil usage. Manufacturers often provide guidelines for oil change intervals based on these factors. It’s important to adhere to these recommendations to ensure optimal engine performance and longevity.

Monitoring Engine Health

Regular monitoring of engine health is essential for optimizing oil change intervals. This involves conducting routine inspections, analyzing oil samples, and performing engine diagnostics. By closely monitoring the engine’s condition, aviation professionals can make informed decisions regarding oil change intervals, ensuring that the engines remain in peak operating condition.

Pre-change Preparations

Prepare for the upcoming oil change during aircraft line maintenance to ensure smooth execution. Gather the necessary tools, assess the engine warm-up status, and collect the oil sample for analysis. Proper preparation is key to maintaining the aircraft engine’s optimal performance.

Safety Protocols

Before conducting an aircraft line maintenance engine oil change, prioritize safety protocols to ensure a secure work environment.

Tools And Equipment Checklist

Refer to the tools and equipment checklist to guarantee all necessary items are readily available for a smooth oil change process.

Executing The Oil Change

Performing regular oil changes is crucial for maintaining the health and performance of aircraft engines. The process involves precise steps to ensure the engine is properly lubricated and protected. Let’s delve into the step-by-step procedure and troubleshooting common issues when executing an oil change.

Step-by-step Procedure

- Prepare the necessary tools and equipment, including new oil, oil filter, drain pan, and safety gear.

- Locate the drain plug and oil filter on the aircraft engine.

- Place the drain pan beneath the drain plug to collect the old oil.

- Unscrew the drain plug and allow the old oil to drain completely.

- Remove the old oil filter and replace it with a new one, ensuring it is securely fitted.

- Refill the engine with the appropriate amount of new oil, as per the manufacturer’s specifications.

- Check the oil level using the dipstick and adjust if necessary.

- Dispose of the old oil and filter in an environmentally friendly manner.

- Run the engine briefly to circulate the new oil and check for any leaks.

Troubleshooting Common Issues

- Oil Leaks: Check for loose drain plug or filter, damaged gaskets, or overfilled oil levels.

- Oil Contamination: Look for signs of water or debris in the oil, indicating potential engine issues.

- Incorrect Oil Type: Ensure the oil used meets the specifications recommended by the aircraft manufacturer.

- Improper Installation: Double-check that the drain plug and filter are correctly installed to prevent leaks.

- Oil Overfill: Avoid overfilling the engine with oil, as it can lead to excessive pressure and damage.

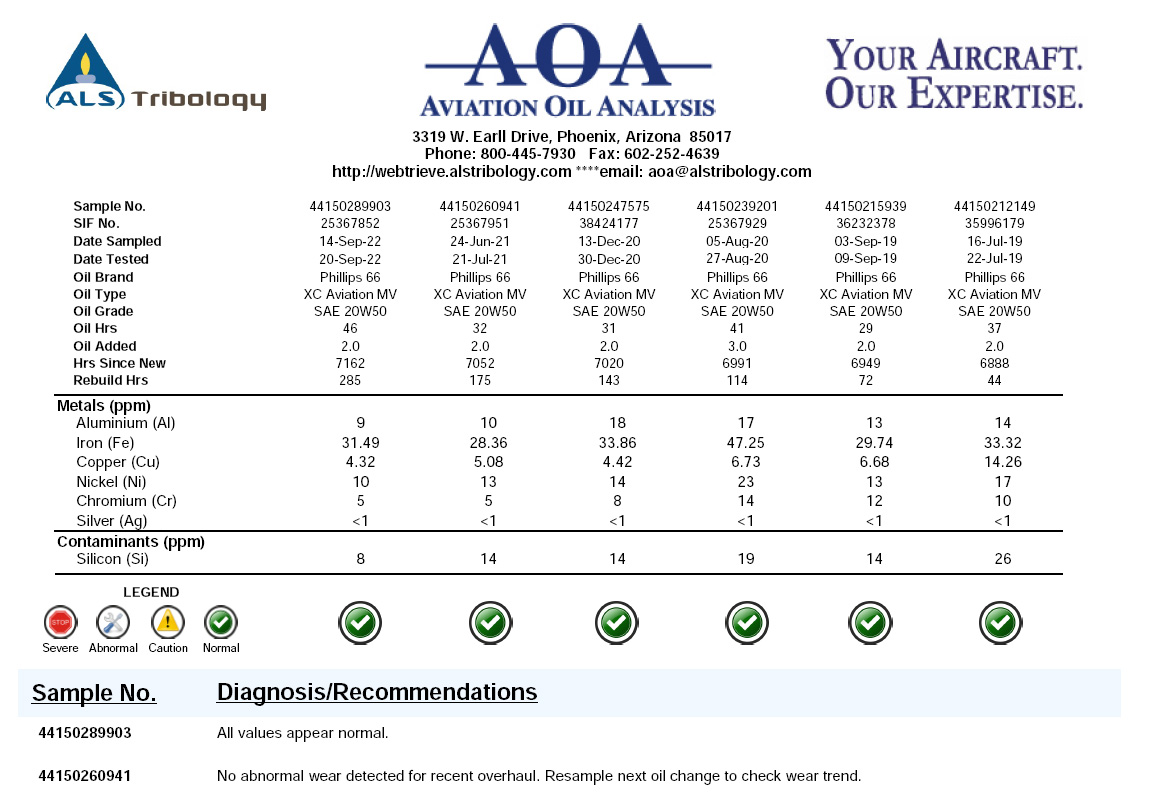

Oil Sampling And Analysis

Oil sampling and analysis are crucial aspects of aircraft line maintenance engine oil management. By collecting representative samples and interpreting analysis reports, aviation professionals can gain valuable insights into the health and performance of the engine oil, enabling them to make informed maintenance decisions.

Collecting A Representative Sample

When collecting a sample of aircraft engine oil, it’s essential to ensure that the sample is representative of the oil within the system. This involves following specific procedures to obtain a sample that accurately reflects the condition of the oil. Typically, the following steps are taken:

- Use a clean, dry sampling container to avoid contamination.

- Collect the sample from the middle of the oil stream to capture a representative sample.

- Ensure the sampling location is accessible and safe for the maintenance personnel.

Interpreting Analysis Reports

Once the oil sample has been collected, it undergoes detailed analysis to assess various parameters such as viscosity, metal content, and additive levels. Interpreting the analysis reports requires a thorough understanding of the data provided. The analysis report may include:

- Viscosity measurements to evaluate the oil’s ability to lubricate the engine components.

- Metal content analysis to detect any abnormal wear or component degradation.

- Identification of any contaminants or foreign particles present in the oil.

Post-change Best Practices

Optimizing aircraft line maintenance engine oil post-change best practices ensures efficient and safe operations. Regular analysis and adherence to recommended lubricants are vital for engine longevity and performance. Understanding the differences between aviation and automotive oil is crucial for optimal maintenance.

Post-Change Best Practices After changing the engine oil in an aircraft, it is important to follow some best practices to ensure the engine runs smoothly and safely. Two critical areas that need attention are filter inspection and replacement and proper torque techniques. Filter Inspection and Replacement Inspecting and replacing the oil filter is essential to maintaining the engine’s health. The filter needs to be inspected for any debris or metal particles that could indicate engine wear or damage. If there is any sign of debris or metal, the filter should be replaced immediately. Additionally, it is essential to replace the filter according to the manufacturer’s recommendations or the aircraft’s maintenance manual. Proper Torque Techniques Proper torque techniques are crucial to ensuring that all the nuts, bolts, and fasteners are tightened correctly. Over-tightening or under-tightening can cause serious engine damage or even catastrophic failure. Therefore, it is crucial to use a torque wrench and follow the manufacturer’s recommended torque settings. It is also essential to tighten the fasteners in the correct sequence to ensure even distribution of the load. Following these best practices for filter inspection and replacement and proper torque techniques can significantly extend the life of an aircraft engine and ensure safe and reliable operation.Maintaining Oil System Health

Maintaining the oil system health of aircraft engines is crucial for ensuring optimal performance and safety. Routine checks and maintenance procedures play a pivotal role in preserving the integrity of the oil system, safeguarding the engine, and enhancing overall operational efficiency.

Routine Checks And Balances

Regular inspections and meticulous monitoring are essential to identify any potential issues that may compromise the oil system’s functionality. These checks encompass evaluating oil levels, examining for contaminants, and inspecting the oil filter for any signs of debris accumulation. Timely identification of irregularities allows for prompt corrective action, preventing potential damage and ensuring the smooth operation of the engine.

Establishing A Maintenance Baseline

Establishing a comprehensive maintenance baseline involves documenting crucial oil system parameters, such as oil consumption rates, operating temperatures, and pressure levels. This baseline serves as a reference point for evaluating the system’s performance over time and facilitates the early detection of deviations or anomalies. By adhering to a structured maintenance baseline, aviation professionals can proactively address any emerging issues, mitigating the risk of unexpected oil system malfunctions.

Advanced Tips For Maintenance Efficiency

Efficient maintenance of aircraft engines is crucial for ensuring optimal performance and safety. Here are some advanced tips to enhance maintenance efficiency for aircraft line maintenance engine oil.

Leveraging Technology For Diagnostics

Utilizing advanced diagnostic technology can significantly improve the efficiency of aircraft engine maintenance. Implementing state-of-the-art diagnostic tools and software allows maintenance crews to quickly identify and address potential issues, leading to reduced downtime and enhanced operational reliability.

Continuous Improvement In Maintenance Processes

Embracing a culture of continuous improvement in maintenance processes is essential for maximizing efficiency. Regularly reviewing and refining maintenance procedures based on performance data and industry best practices can lead to streamlined workflows and improved resource allocation.

Credit: www.tyndall.af.mil

Regulatory Compliance And Documentation

Ensuring regulatory compliance and proper documentation is crucial in aircraft line maintenance engine oil procedures. Understanding aviation regulations and maintaining accurate logbook entries are key aspects of this process.

Understanding Aviation Regulations

Aviation regulations govern every aspect of aircraft maintenance, including engine oil changes. Compliance with regulations ensures safety and optimal performance of the aircraft.

Accurate Logbook Entries

Accurate and detailed logbook entries are essential for documenting all maintenance activities related to engine oil changes. These entries provide a historical record of maintenance, aiding in troubleshooting and future maintenance planning.

Comparing Aviation And Automotive Oils

Aircraft line maintenance engine oil plays a crucial role in ensuring the smooth operation of aircraft engines. When it comes to comparing aviation and automotive oils, there are key differences in formulations that have significant implications for aircraft engines.

Key Differences In Formulations

Aviation oils are specifically designed for the high-heat environment of aircraft engines. They contain zinc anti-wear additives and detergent additives that are tailored to the needs of air-cooled piston engines. On the other hand, automotive oils traditionally include metal-containing additives that may not perform well in the extreme conditions of aircraft engines.

Implications For Aircraft Engines

The use of aviation oils in aircraft engines helps to protect against wear and extend the engine’s lifespan. These oils are formulated to handle high temperatures and high-stress conditions, which are common in aviation operations. Conversely, using automotive oils in aircraft engines may lead to premature wear and potential engine damage due to the differences in formulation.

Future Trends In Aircraft Engine Lubricants

Future trends in aircraft engine lubricants are focusing on improved performance and efficiency, as well as meeting environmental regulations. When it comes to aircraft line maintenance engine oil, ashless dispersant (AD) oils are commonly used, as they aid in scavenging debris and carrying it to the filter or screen.

It is important to establish a regular maintenance schedule and perform routine oil analysis to ensure the health and reliability of the aircraft’s engine.

Innovations In Oil Technology

New innovations in aircraft engine lubricants are revolutionizing the aviation industry. Manufacturers are developing advanced synthetic oils that offer superior performance and protection for engines. These oils are designed to enhance efficiency and extend engine life through improved lubrication properties. Additionally, nanotechnology-infused oils are being introduced to provide enhanced thermal stability and wear resistance, ensuring optimal engine operation even in extreme conditions.

Environmental Considerations

With a growing focus on sustainability and environmental impact, the aviation industry is shifting towards bio-based lubricants derived from renewable sources. These eco-friendly oils not only reduce carbon footprint but also offer comparable performance to traditional lubricants. Manufacturers are also exploring biodegradable oils that minimize environmental harm in case of leaks or spills, aligning with green initiatives across the aviation sector.

Credit: www.bloomberg.com

Frequently Asked Questions

What Kind Of Oil Do Aircraft Engines Use?

Aircraft engines use mineral oils with ashless dispersant (AD) additives to scavenge debris and carry it to the filter. These oils are specifically designed for the high-heat environment of air-cooled piston engines.

How Often Should You Change Aircraft Engine Oil?

Change aircraft engine oil every 50 to 100 flight hours for optimal performance and maintenance.

What Is The Difference Between Aviation Oil And Automotive Oil?

Aviation oil differs from automotive oil due to specific additives that are unsuitable for aircraft engines.

What Are The Recommended Aircraft Engine Lubricants?

The recommended aircraft engine lubricants are ashless dispersant (AD) and mineral oils. These oils are highly refined and petroleum-based, suitable for aircraft engines.

Conclusion

Regular maintenance and proper oil analysis are crucial for aircraft engine performance. Understanding the difference between aviation and automotive oil is key. By using recommended lubricants and following oil change guidelines, you can ensure the longevity and efficiency of your aircraft engine.