To find grease for automotive use, search for MP grease, also known as multi-purpose grease, suitable for automotive applications. MP grease provides protection from elements and water, ensuring parts are well-protected and lubricated.

When selecting grease, consider factors such as NLGI grade, base oil viscosity, EP additives, and specific requirements for your application. Grease viscosity plays a crucial role in stability and friction protection, with higher viscosity ideal for heavy loads and lower viscosity suitable for high-speed applications.

Understanding these factors will help you choose the right grease for your automotive needs, ensuring optimal performance and longevity for your vehicle.

Credit: heartautocare.com

Choosing The Right Grease

White Lithium Grease

White lithium grease is ideal for metal-to-metal applications and offers excellent corrosion protection.

Multi-vehicle Grease

Multi-vehicle grease, also known as MP grease, is versatile and suitable for automotive and light vehicle applications.

High-temperature Wheel Bearing Grease

High-temperature wheel bearing grease is designed to withstand extreme heat and offers superior performance for wheel bearing applications.

When selecting grease for automotive use, consider factors like the specific application, temperature requirements, and compatibility with materials to ensure optimal performance.

Credit: heartautocare.com

Identifying Vehicle Grease Points

When it comes to maintaining your vehicle, one important aspect is ensuring that all the grease points are properly lubricated. Grease plays a crucial role in reducing friction and preventing wear and tear on various automotive components. Identifying the grease points in your vehicle and using the right type of grease is essential for optimal performance and longevity. In this article, we will explore the grease points, specifically focusing on the power steering system, drum brakes, and pitman arm.

Power Steering System

The power steering system of your vehicle is responsible for making steering easier and more manageable. It consists of various components, such as the steering pump, steering gear, and steering linkage. To identify the grease points in the power steering system, refer to your vehicle’s owner’s manual or consult a professional mechanic. Common grease points in the power steering system include:

- Steering pump pulley

- Steering gear input shaft

- Steering gear, pitman shaft

- Steering linkage ball joints

- Steering linkage tie rod ends

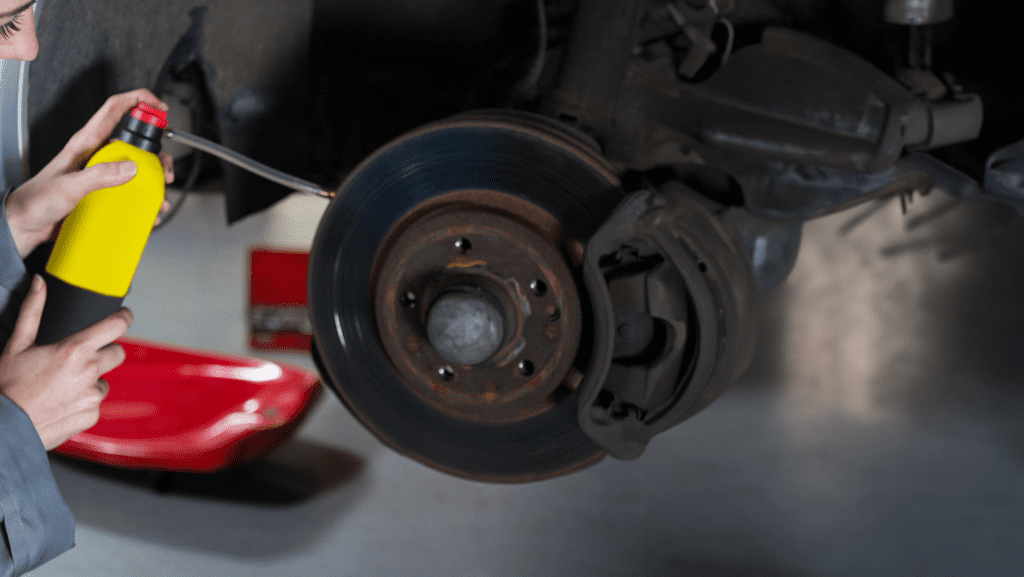

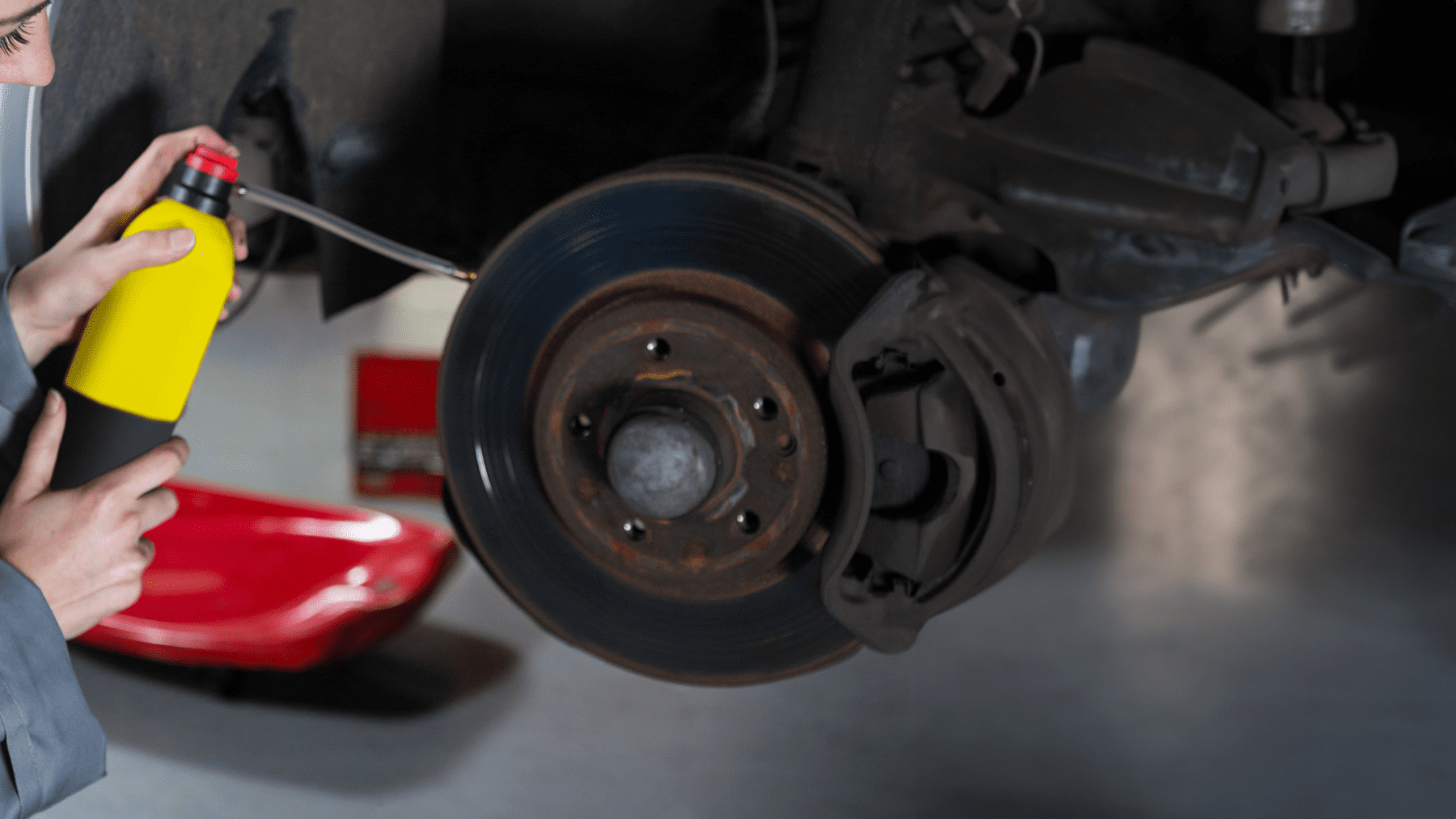

Drum Brakes

Drum brakes are a type of braking system commonly found in older vehicles. They consist of brake shoes, brake drums, and various linkages. Proper lubrication of the grease points in drum brakes is essential for smooth operation and effective braking. To identify the grease points in drum brakes, you can:

- Refer to your vehicle’s owner’s manual

- Consult a professional mechanic

The grease points in drum brakes typically include:

- Brake shoe backing plate contact points

- Brake adjuster threads

- Brake shoe anchor pins

Pitman Arm

The pitman arm is part of the steering linkage in your vehicle and connects the steering gear to the steering linkage. It is responsible for transmitting the steering motion from the steering gear to the wheels. Proper lubrication of the pitman arm grease points is crucial for smooth and accurate steering. To identify the grease points in the pitman arm, you can:

- Refer to your vehicle’s owner’s manual

- Consult a professional mechanic

The grease points in the pitman arm typically include:

- Pitman arm shaft

- Pitman arm ball joint

Selecting The Appropriate Grease

For automotive use, finding the right grease involves selecting the appropriate consistency grade according to NLGI standards. Consider the required base oil viscosity and the presence of EP additives for optimal performance and protection against friction. Additional requirements should be checked to ensure the grease meets specific needs in various applications.

Nlgi Gclb Certification

When it comes to selecting the appropriate grease for automotive use, one important factor to consider is the NLGI GCLB certification. NLGI stands for the National Lubricating Grease Institute, and their certification ensures that the grease meets certain industry standards and performance requirements.

NLGI GCLB certification is particularly important for automotive applications as it guarantees that the grease has been tested and proven to provide adequate lubrication and protection in a wide range of temperatures and operating conditions. It gives car owners and mechanics peace of mind knowing that the grease they are using is of high quality and will effectively reduce friction and wear on components.

High-temp Grease

In the automotive industry, high temperatures are a common factor that grease needs to withstand. High-temperature grease is specifically formulated to handle the extreme heat generated by engine parts, such as wheel bearings and chassis components, which can reach temperatures of up to 200 degrees Celsius.

This type of grease is designed to remain stable and provide lubrication even under extreme heat and heavy loads. It has a higher dropping point, which is the temperature at which the grease begins to melt and lose its lubricating properties. Using high-temp grease ensures that the automotive components are adequately protected and can operate smoothly even in high-temperature conditions.

Synthetic Blend Greases

Synthetic blend greases combine the benefits of both mineral oil-based and synthetic greases. They offer enhanced performance and durability compared to conventional greases while still being cost-effective. Synthetic blend greases are ideal for automotive applications where a balance between performance and cost is desired.

These greases have excellent temperature stability, oxidation resistance, and water resistance, making them suitable for various automotive components, including chassis fittings, ball joints, and universal joints. Their unique formulation provides superior protection against wear and corrosion, ensuring longer service life and reduced maintenance requirements.

Full Synthetic Grease

For automotive applications where maximum performance and protection are required, full synthetic grease is the ideal choice. Full synthetic greases are made from high-quality synthetic base oils and advanced additives, offering superior lubrication and protection properties.

These greases have exceptional temperature resistance, stability, and shear strength, making them suitable for heavy-duty applications, such as wheel bearings, CV joints, and suspension systems. Full synthetic greases also provide excellent water resistance, helping to prevent rust and corrosion in automotive components exposed to moisture.

By selecting the appropriate grease for automotive use based on factors such as NLGI GCLB certification, temperature requirements, and synthetic blend or full synthetic formulations, car owners and mechanics can ensure that their vehicles’ components are adequately lubricated and protected for optimal performance and longevity.

Credit: www.redlabelabrasives.com

Understanding Grease Selection

Selecting the right grease for automotive use involves understanding various grease types, including white lithium grease, multi-vehicle grease, and high-temperature wheel bearing grease. To find the suitable grease, consider the National Lubricating Grease Institute (NLGI) consistency grade, base oil viscosity, EP additives, and specific application requirements.

Grease viscosity plays a key role in determining its protective properties against friction.

Consistency Grade

Greases are classified into different consistency grades by the NLGI.

Base Oil Viscosity

Identify the necessary base oil viscosity for optimal performance.

Ep Additives

Ensure the inclusion of EP additives for enhanced protection under extreme pressure.

Additional Requirements

Consider any extra specifications or requirements for your specific application.

Choosing the right grease for automotive use involves understanding different factors like the consistency grade, base oil viscosity, EP additives, and any additional requirements.

Impact Of Grease Viscosity

Selecting the right grease for automotive use hinges on understanding the viscosity impact. Grease viscosity determines its stability and effectiveness in protecting against friction. High viscosity is best for heavy, slow loads, while lower viscosity suits high-speed applications. This knowledge helps in choosing the right grease for automotive machinery.

Stability Under Heavy, Slow Loads

When it comes to finding the right grease for automotive use, understanding the impact of grease viscosity is crucial. Grease viscosity refers to the thickness or resistance of the grease to flow. It plays a vital role in determining the grease’s stability under heavy, slow loads. Heavy machinery and vehicles often operate under extreme loads and at low speeds, causing significant stress on the lubricating grease. Therefore, choosing a grease with a suitable viscosity is essential to ensuring proper lubrication and preventing machinery failures.

Suitability For High-speed Applications

In addition to stability under heavy, slow loads, grease viscosity also affects its suitability for high-speed applications. High-speed machinery and vehicles require lubricants that can withstand high RPMs and provide adequate lubrication to prevent friction and wear. Greases with lower viscosity are better suited for high-speed applications as they can flow more easily, reaching all the necessary lubrication points quickly. On the other hand, greases with higher viscosity tend to resist flow and may not provide sufficient lubrication under high-speed conditions.

Table Of Grease Viscosity Grades

| Viscosity Grade | Description |

|---|---|

| 0 | Fluid |

| 1 | Very soft |

| 2 | Soft |

| 3 | Semi-fluid |

| 4 | Firm |

| 5 | Stiff |

It is important to note that grease viscosity is typically classified using the National Lubricating Grease Institute’s (NLGI) system. The NLGI assigns a number grade to indicate the consistency of grease, with lower numbers representing lower viscosity or softer grease and higher numbers representing higher viscosity or firmer grease. For example, NLGI grade 0 greases are fluid, while grade 2 greases are soft and commonly used in automotive applications.

In conclusion, when selecting grease for automotive use, considering the impact of grease viscosity is crucial. Stability under heavy, slow loads and suitability for high-speed applications are key factors to evaluate. Choosing a grease with the appropriate viscosity grade ensures effective lubrication, extends machinery lifespan, and reduces the risk of failure.

Differences Between Automotive and Other Greases

When it comes to finding the right grease for automotive use, it’s important to understand the differences between automotive and other greases. While greases are generally designed to provide lubrication and protect various parts, automotive greases are specifically formulated to meet the unique needs and demands of vehicles. Here are some key differences to keep in mind:

Organic Result: Understanding Differences

Organic greases, also known as petroleum-based or mineral-based greases, are commonly used in various applications. However, when it comes to automotive use, there are some notable differences. Automotive greases are formulated to withstand the higher temperatures and pressures that are often encountered in vehicles. They also have additives to provide better protection against rust, corrosion, and wear, which are common issues in automotive components.

Read More: Difference Between Motor Oil and Grease

Silicone-based Grease in Automotive Applications

Silicone-based greases offer unique properties that make them suitable for specific automotive applications. These greases have excellent resistance to high temperatures, making them ideal for components that are exposed to extreme heat, such as brake systems and exhaust systems. They also offer good water resistance, which is important for parts that may come into contact with moisture or are exposed to water.

Table

| Properties | Automotive Grease | Other Greases |

|---|---|---|

| Temperature Resistance | High | Varies |

| Pressure Resistance | High | Varies |

| Protection Against Rust and Corrosion | Enhanced | Varies |

| Water Resistance | Varies | Varies |

- Automotive greases are formulated to withstand higher temperatures and pressures than other greases.

- They provide enhanced protection against rust, corrosion, and wear.

- Silicone-based greases are commonly used in automotive applications that require high temperatures and water resistance.

- Select the appropriate consistency grade based on National Lubricating Grease Institute (NLGI) guidelines.

- Determine the required base oil viscosity for the specific application.

- Verify the presence of EP (extreme pressure) additives if needed.

- Consider any additional requirements or specifications.

An appropriate grease selection process comprises four steps:

When selecting grease, it’s important to consider the specific requirements of the automotive application. The right grease can help protect and prolong the life of important components, ensuring smoother and more reliable performance.

Remember, always consult the manufacturer’s recommendations and guidelines to ensure you are using the correct grease for your automotive needs.

Conclusion & Recommendations

Discovering the ideal grease for your automotive needs is crucial. Explore a variety of options, including white lithium and multi-vehicle grease, and consider factors like NLGI certification and base oil viscosity for optimal lubrication solutions. Make informed choices for optimal vehicle performance.

Choosing the right grease for automotive use is crucial to ensuring the longevity and efficient performance of your vehicles. By considering factors such as temperature, load, and speed, you can select the most suitable grease for your specific application. Below are some recommendations to guide you in finding the appropriate grease for automotive use.

Factors To Consider When Choosing Grease

When selecting grease for automotive applications, it’s essential to consider the following factors:

- Temperature range

- Load-bearing capacity

- Speed ratings

- Corrosion resistance

- Water resistance

Application-specific Recommendations

For different automotive components and systems, the following recommendations can be helpful:

| Automotive Component/ System | Recommended Grease Type |

|---|---|

| Wheel bearings | High-temperature wheel bearing grease |

| Chassis fittings | Multi-vehicle grease with EP additives |

| Power steering system | General purpose lithium-based grease |

Frequently Asked Questions on How to Find Grease for Automotive Use?

What Kind of Grease Do You Use for Automotive?

For automotive use, multi-purpose (MP) grease is commonly used. MP grease provides a protective coating against elements and water, ensuring the parts are well-protected. When selecting grease, consider the consistency grade, base oil viscosity, presence of EP additives, and any additional requirements.

Grease viscosity matters, as higher viscosity is suited for heavy, slow loads, while lower viscosity is ideal for high-speed applications. Silicone-based grease is used for lubricating rubber seals and gaskets in automotive applications.

How Do I Know What Grease to Use?

To determine the right grease to use, follow these steps: 1. Select the appropriate consistency grade based on the NLGI classification. 2. Determine the required base oil viscosity. 3. Verify the presence of EP additives. 4. Check for any additional, specific requirements.

Following this process will help you choose the right grease for your needs.

Does it Matter What Kind of Grease You Use?

The type of grease used matters; viscosity affects stability and protection against friction. Higher viscosity suits heavy loads, while lower viscosity is ideal for high-speed applications.

What Is the Difference Between #1 and #2 Grease?

#1 grease is suitable for low to moderate temperatures, while #2 grease is ideal for higher temperatures and heavy loads.

Conclusion

Choosing the right grease for automotive use is crucial for protecting your vehicle’s parts. Understanding NLGI grades and base oil viscosity is key. Remember, grease selection impacts stability and friction protection. Make an informed decision to ensure the optimal performance and longevity of your vehicle.